Controlling and monitoring materials and purchase operations that affects production, maintenance and other down supplychain activities and up supplychain demand, is a highly critical and volatile department to monitor.

It is essential that we monitor various areas of Materials management like stock availability, vendor segmentation, demand and quality fulfilment efficiency, Inventory aging and purchase trends and statistics and many more insights on a regular frequency (normally monthly) to ensure we are keeping our inventory on check and good enough to keep the production lines up and running.

Vendor Trends per different segments like geography, purchase value and growth,

frequency, quality satisfaction, returns etc compared with historical data.

Material price variation analysis.

Benchmarking Key Performance Indicators and monitoring as per industry standards.

Inventory and trends based on historical data.

Forecast future purchase and predictions to communicate to vendors.

Measure and improve procure to pay time.

Measure and improve putaway and production stock availability efficiency.

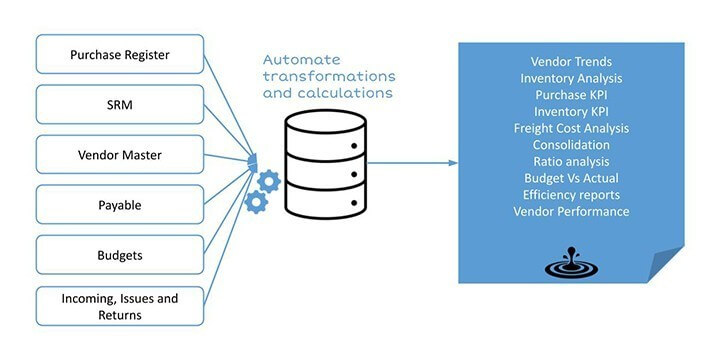

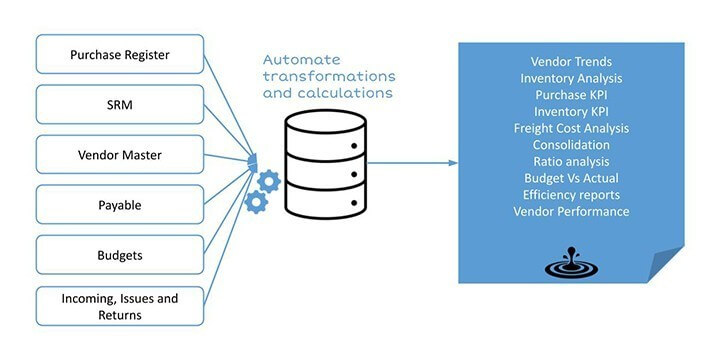

Incremental data extraction and transformation.

Simple, Reliable and Automated Reporting and KPI.

360 deg view of your company performance.

Automatic sharing of information and reports to users.